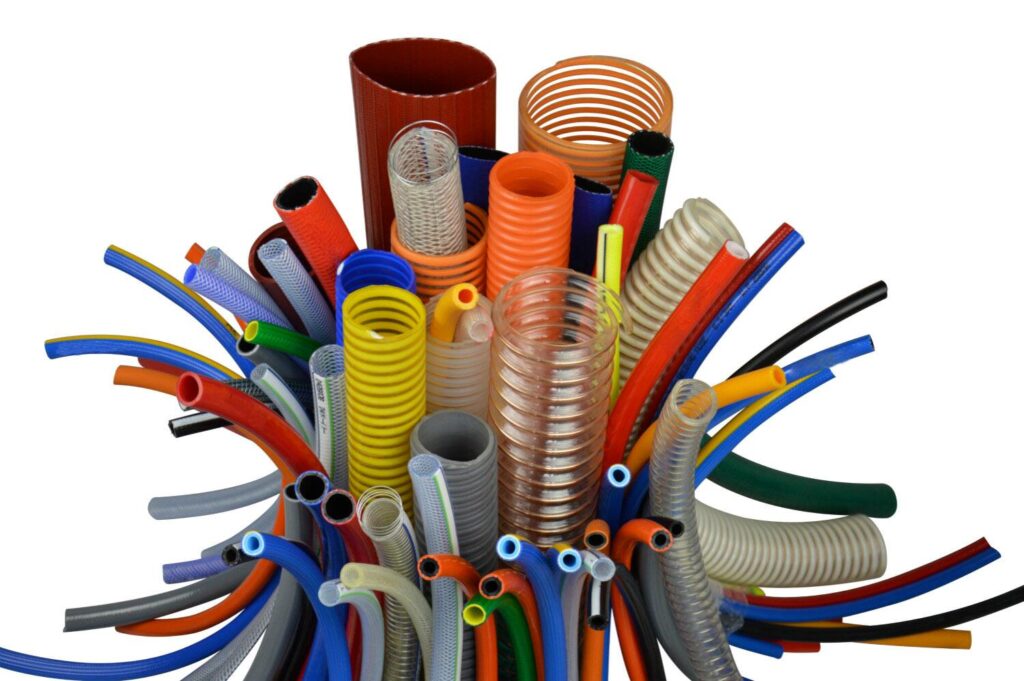

In an era where efficiency, durability, and adaptability are paramount, PVC HOSE Manufacturer have emerged as game-changers across multiple industries. From agriculture and construction to pharmaceuticals and food processing, these hoses are providing flexible, reliable solutions for transporting liquids, gases, and materials. The unique combination of flexibility and toughness makes PVC hoses indispensable for modern industries, enabling them to improve operational efficiency and reduce costs. But how exactly are PVC hoses revolutionizing the industrial landscape? Let’s take a closer look.

The Power of Flexibility

One of the standout characteristics of PVC hoses is their flexibility. This makes them easy to install, maneuver, and work with, even in tight or confined spaces. Whether it’s winding through intricate industrial machinery or connecting distant sections of a fluid transport system, PVC hoses bend without breaking. In agriculture, for example, flexible PVC hoses can be easily routed through complex irrigation systems, providing a seamless flow of water to crops.

In industries like construction, where equipment often moves and shifts, the ability to quickly adjust hose positions without sacrificing durability is invaluable. PVC hoses make the job easier by allowing workers to easily adapt them to the specific needs of each task, whether it’s pumping water or transferring concrete mixtures. Flexibility in such environments translates to faster installation times, reduced labor costs, and improved operational efficiency.

Durability: Built to Last

Though they are lightweight and flexible, PVC hoses are surprisingly tough. Their resistance to wear and tear is one of the main reasons they have become a staple in various industries. Designed to withstand harsh working conditions, PVC hoses are resistant to abrasion, chemicals, and extreme temperatures. Whether dealing with corrosive chemicals in a laboratory setting or facing abrasive materials on a construction site, PVC hoses hold up where other materials might fail.

Another reason for the durability of PVC hoses is their resistance to UV radiation and weathering. Outdoor applications, such as in agriculture or construction, often expose hoses to prolonged sunlight, which can degrade many materials over time. PVC, however, remains durable even after extended sun exposure, making it an excellent choice for outdoor environments. In colder climates, the material’s resilience against freezing conditions helps ensure continuous operation, preventing costly downtimes.

Versatility Across Industries

One of the most significant ways PVC hoses are revolutionizing industries is through their versatility. Different sectors have unique requirements, and PVC hoses can be tailored to meet these specific needs. For example, food-grade PVC hoses are used in food processing and beverage industries because they are non-toxic, odorless, and meet strict sanitary standards. These hoses are often transparent, allowing operators to monitor fluid transfer and ensure quality control at every stage.

In the medical and pharmaceutical industries, PVC hoses are used in equipment for transferring sensitive liquids or gases. Their smooth interior prevents any buildup of particles or contaminants, making them ideal for applications where hygiene and precision are critical.

Similarly, industrial-grade PVC hoses serve a variety of purposes in manufacturing plants, such as transporting gases or liquids in chemical processing plants, or vacuum and dust extraction in factories. PVC hoses are also widely used in the automotive industry, where they handle everything from air lines to fuel transfer. Their ability to withstand pressure and resist chemical degradation makes them the go-to choice in this demanding field.

Cost-Effective and Sustainable

PVC hoses are not only durable and versatile, but they are also cost-effective. Compared to other materials like rubber or metal, PVC is relatively inexpensive to produce and maintain. The long lifespan of PVC hoses reduces the need for frequent replacements, further lowering maintenance costs for industries. Their lightweight nature also means that transportation and installation are easier and more affordable.

Moreover, advancements in PVC manufacturing have led to more sustainable production methods. Many manufacturers are now focusing on eco-friendly processes, using recyclable PVC materials and reducing harmful emissions during production. This shift toward sustainability is helping industries meet environmental standards without sacrificing performance or cost-efficiency.

Driving Future Innovation

As industries continue to evolve, the demand for more advanced, durable, and flexible solutions will only increase. PVC hoses, with their unique combination of strength and adaptability, are positioned to meet these growing needs. In the future, we can expect even more innovations, such as hoses with integrated sensors for real-time monitoring of fluid flow, pressure, and temperature, further enhancing operational efficiency and safety.

Additionally, the trend toward customization will likely grow, with manufacturers offering more tailored solutions for specific applications. Whether it’s creating anti-static hoses for chemical plants or reinforced hoses for high-pressure hydraulic systems, the flexibility of PVC as a material ensures that it will continue to be at the forefront of industrial innovation.

Conclusion: Revolutionizing with Flexibility and Strength

PVC hoses have transformed the way industries operate by providing flexible, tough, and cost-effective solutions across a wide range of applications. From agriculture to pharmaceuticals, these hoses have proven themselves to be essential tools that enable industries to increase efficiency, reduce costs, and meet ever-growing demands. As innovations in PVC hose manufacturing continue, industries will benefit from even more advanced, durable, and customizable options, cementing the role of PVC HOSE Manufacturer in shaping the future of industrial processes.